Garage door rollers play a crucial role in ensuring the smooth operation of your garage door. These small but essential components allow the door to move effortlessly along its tracks, providing convenience and functionality in daily use. However, over time, dirt, grime, and general wear can accumulate on the rollers, leading to increased noise, slower movement, or even damage to the door’s mechanism. Neglecting routine maintenance can result in costly repairs or the need for replacements.

The purpose of this article is to provide a comprehensive, step-by-step guide on how to clean garage door rollers effectively. By following this guide, you can maintain the performance of your garage door, reduce unnecessary wear, and extend the lifespan of its rollers, ensuring long-term smooth operation.

Understanding Garage Door Rollers

What Are Garage Door Rollers?

Garage door rollers are essential components of the garage door system. They guide the door along its tracks during opening and closing. These small but robust wheels are fitted to the door’s edges and glide smoothly within the door tracks, ensuring efficient movement. The door’s operation can become unreliable, noisy, or even dangerous without properly functioning rollers.

Types of Rollers

There are two primary types of garage door rollers: steel rollers and nylon rollers.

- Steel Rollers: These are highly durable and can handle heavy loads, making them ideal for larger or commercial garage doors. However, they can be noisy during operation and may require more frequent lubrication to reduce friction.

- Nylon Rollers: Known for their quiet operation, nylon rollers are suitable for residential garage doors. They require less maintenance than steel rollers and are resistant to corrosion, but they may have a shorter lifespan and are less suitable for heavy-duty use.

Common Problems Caused by Dirty or Damaged Rollers

When garage door rollers become dirty, worn, or damaged, they can lead to a range of issues. These include excessive noise, jerky or uneven movement, misalignment of the door along the tracks, and additional wear on other connected components. Addressing roller issues promptly is crucial to avoid more significant damage and costly repairs.

Tools and Materials Needed

Before beginning cleaning or replacing garage door rollers, it is important to gather the necessary tools and materials for an effective and safe job. Essential tools include a wrench set, screwdriver, rag, lubricant, cleaning brush, and safety gloves. These items will allow you to access, clean, and maintain the rollers properly. For cleaning agents, mild detergent, soapy water, or specialized cleaners designed for garage door components are recommended to remove dirt and grime effectively.

Safety precautions are vital before starting the cleaning process. Ensure the power to the garage door opener is disconnected to prevent accidental activation. Wear safety gloves to protect your hands, especially when handling potentially sharp or dirty parts. Additionally, inspect the area for stable footing and clear any obstructions from the work area to maintain a safe and efficient environment.

Preparing for Roller Cleaning

Safety First

Before beginning the cleaning process, prioritize safety to avoid potential accidents. Start by disconnecting the garage door opener to ensure the door cannot move unexpectedly during the procedure. If possible, secure the door in the open position using clamps or locks to keep it stable. This will provide a safer working environment and better access to the rollers and tracks.

Inspecting the Rollers and Tracks

Take a moment to closely examine the rollers and tracks. Look for any visible dirt, debris, rust, or signs of damage. Identifying these issues beforehand will help you determine whether simple cleaning or additional maintenance is required. Pay special attention to cracks or excessive wear, as these may indicate the need for part replacement.

Setting Up Your Workspace

Prepare your workspace to make the cleaning process efficient and organized. Clear the area around the garage door to remove any potential tripping hazards or obstructions. Lay down protective covers beneath the door to catch debris or cleaning solutions, preventing unnecessary mess. A well-prepared workspace ensures that you complete the task smoothly and effectively while maintaining a clean and safe environment.

How to Clean Garage Door Rollers: Step-by-Step Cleaning Process

Removing Loose Dirt and Debris

Begin by using a brush or a rag to wipe away any loose dirt or debris from the garage door rollers. This step removes surface grime and ensures that you’re not working on a buildup of dust and dirt, which can interfere with the cleaning process. Pay attention to the edges and crevices where dirt accumulates most.

Cleaning Rollers Thoroughly

Apply a suitable cleaning solution to the rollers to eliminate grease, grime, and any accumulated buildup. Carefully scrub the rollers with a soft brush or cloth, ensuring that you clean every part. Avoid using harsh chemicals that could damage the rollers’ material. Once cleaned, wipe the rollers with a clean cloth to remove any remaining solution.

Cleaning Tracks

The tracks of your garage door are equally important for smooth movement. Using a vacuum, brush, or damp rag, remove any debris, small stones, or other obstructions from the tracks. Ensure that the tracks are clear along the entire length. Be gentle to avoid denting or bending the tracks during this process.

Drying and Inspecting

After cleaning the rollers and tracks, wipe them dry thoroughly with a clean, dry cloth. Drying is crucial to prevent rust or corrosion over time. Once dry, inspect each roller for signs of damage such as cracks, flat spots, or excessive wear. Similarly, check the tracks for any dents, rust, or misalignment. Addressing these issues early can prevent larger problems in the future.

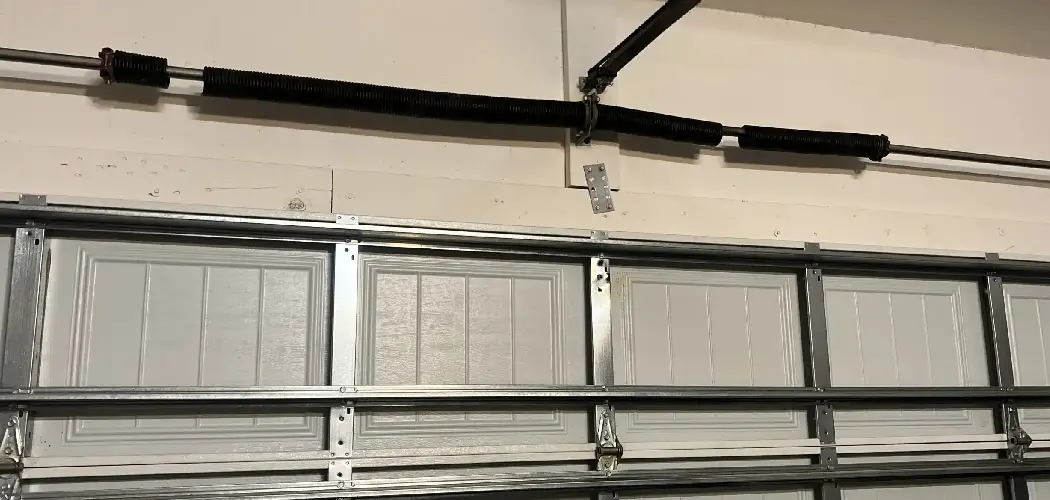

Reinstalling or Adjusting Rollers (if needed)

If you notice any loose or damaged rollers during the inspection, tighten the bolts holding the rollers in place. If a roller is worn out or cracked, replace it with a new one. Follow the manufacturer’s instructions for proper installation. Properly aligned and securely fastened rollers ensure the smooth operation of your garage door, contributing to its longevity and reliability.

Lubricating Garage Door Rollers

Proper lubrication of garage door rollers is essential for maintaining smooth and quiet operation. This simple maintenance task can extend the life of your rollers and improve the overall efficiency of your garage door system.

Choosing the Right Lubricant

Selecting the appropriate lubricant for your rollers is crucial to ensure optimal performance. Recommended options include silicone spray, lithium grease, or garage door-specific lubricants. Avoid using heavy oils or WD-40, as they may attract dirt and debris, leading to potential roller damage over time.

How to Apply Lubricant Properly

To correctly apply lubricant, clean the rollers and tracks to remove dust and grime. Spray or apply a light coat of lubricant directly onto the roller bearings, ensuring they are evenly covered. Apply a small amount to the tracks as well to promote smoother movement. Be careful not to over-apply, as excess lubricant can accumulate dirt, reducing the system’s efficiency and causing additional wear.

Frequency of Lubrication

Lubricate your garage door rollers approximately every six months for optimal performance. More frequent lubrication may be needed if you use your garage door heavily or live in an area with extreme weather conditions. Regular maintenance like this keeps your garage door functioning reliably and prevents unnecessary wear and tear.

Tips for Maintaining Rollers and Extending Their Life

Regular Cleaning and Lubrication Schedule

To ensure the longevity of your garage door rollers, follow a consistent cleaning and lubrication routine. Remove dirt and debris from the rollers and tracks regularly, and apply a high-quality lubricant every six months or as needed based on usage and environmental factors.

Avoiding Harsh Chemicals That Can Damage Rollers

Avoid using harsh or corrosive chemicals during cleaning, as they can degrade the material of the rollers over time. Instead, opt for mild, safe cleaning solutions for both the rollers and the tracks.

Inspecting Rollers Periodically for Wear and Replacing Them as Needed

Perform periodic inspections of your rollers to check for signs of wear, such as cracks, flattening, or excessive noise during operation. Replace any damaged rollers promptly to prevent further strain on your garage door system.

Keeping the Tracks Clean to Reduce Strain on Rollers

Ensure the tracks are free from dirt, dust, and obstructions. Clean tracks reduce friction and strain, allowing the rollers to move smoothly and improving the overall efficiency of your garage door.

Common Issues and Troubleshooting

Noisy Rollers Despite Cleaning: Possible Causes and Solutions

If your garage door rollers remain noisy even after cleaning, the issue may stem from inadequate lubrication, dirty bearings, or damaged rollers. Apply a silicone-based lubricant to the rollers and check for any hidden debris lodged in or around the bearings. If noise persists, inspect the rollers for cracks or signs of wear and replace them as necessary.

Rollers Not Rolling Smoothly: Checking for Track Alignment or Damaged Rollers

When rollers fail to glide smoothly along the tracks, check for track misalignment or bends that could obstruct movement. Loose bolts or brackets may cause tracks to shift out of alignment, so tighten them if needed. Additionally, inspect the rollers for wear or deformation, which can hinder smooth rolling, and replace any damaged rollers promptly.

When to Replace vs. Clean Rollers

While cleaning and lubricating rollers can resolve many minor issues, severely worn, cracked, or flattened rollers should be replaced rather than cleaned. Proper maintenance can extend a roller’s lifespan, but replacement is necessary when cleaning no longer restores functionality.

Signs of Worn-out Rollers Requiring Professional Help

Seek professional assistance if you notice uneven door movement, excessive noise, or visible roller damage such as cracks or splits. A professional can assess the issue thoroughly, ensuring safe and efficient repair or replacement of damaged rollers.

Conclusion

Maintaining clean garage door rollers is essential for ensuring smooth operation and extending the lifespan of your garage door system. Regular care and attention can prevent minor issues from escalating into costly repairs, saving you time and money in the long run. By learning the proper steps on how to clean garage door rollers, you contribute to the overall efficiency and safety of the system. Remember to always follow recommended safety procedures during cleaning, such as disconnecting the door and using appropriate tools, to avoid accidents. Prioritize regular maintenance to keep your garage door functioning optimally for years to come.

You Can Check It Out To Clean Garage Door Tracks

I am Rick. I grew up helping my dad with his handyman service. I learned a lot from him about how to fix things, and also about how to work hard and take care of business. These days, I’m still into fixing things- only now, I’m doing it for a living.

I’m always looking for new ways to help people grow and develop. That’s why I have created this blog to share all my experience and knowledge so

that I can help people who are interested in DIY repair.